How to Utilize IoT to Boost Your Industrial Automation

The emergence of the Internet of Things was due to the increased needs of the production sector. In the search for solutions to remove the human factor and optimize the factory performance, the key concept of the IoT was formed. Creating a system of connected devices to get the most out of the data they collect. Now, after more than 15 years of intensive development of IoT automation solutions, we can confidently highlight its main insights that have transformed into stable trends, as well as solutions in the “hot development” stage, which have great prospects. PSA is pleased to reveal the trends we notice with our own eyes.

Industrial Automation: How IoT Makes it Smart

Industrial Automation (IA) – is an approach to managing production processes based on the use of automatic devices to execute operation and control functions. Industrial automation involves both the collection of data to provide inputs to equipment and the performance of an action based on the processed data. So, what has changed through the internet? First, flexibility has appeared. The Internet of Things gives data an immense advantage – access to the cloud. There are much greater opportunities both for data processing and analysis. In IoT ecosystem, all the data on the production process reaches the cloud, hence, you can take advantage of it. In addition, IoT-based automation solutions are much easier to scale and repurpose to meet changing industrial needs.

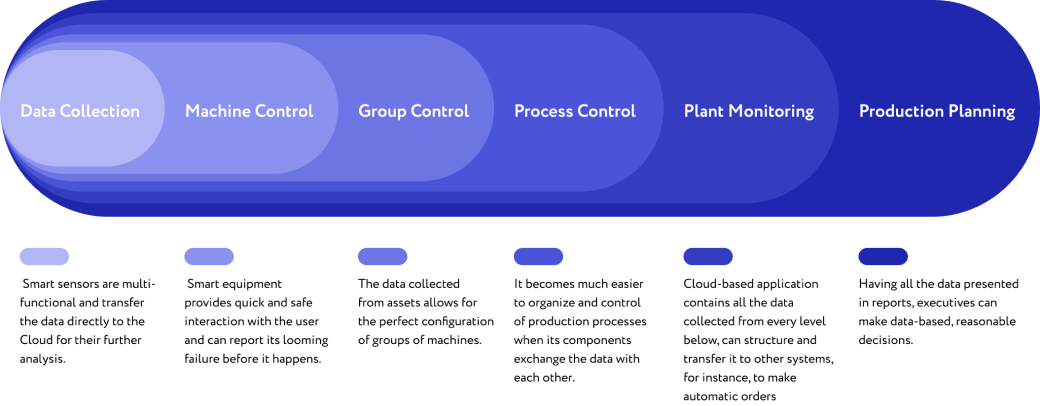

The main trend in manufacturing is to make it smarter and more independent through the updates of the equipment fleet with machines already implemented IoT support. Surely, you can hang smart sensors on every existing machine and it will work too. However, the emphasis is, and rightly so, on the development of products for industrial automation with support for the functionality of the Internet of Things. This helps companies initially put improved capabilities at each level of the manufacturing automation system:

This is what we call Smart Automation.

Industrial Automation: What to Focus On When Developing a Corresponding Solution

Not all enterprises are ready to turn their factory into smart ones overnight, which is certainly reasonable. However, by deploying IoT-based industrial automation solutions even on a small scale, the company will not lose. For example, you can start to intelligently automate a specific manufacturing process, or enhance control for the group of equipment through IoT. The vector of development of modern smart systems is directly opposite to the traditional factory and assumes comprehensive compatibility. Thanks to this, it becomes much easier to scale such solutions.

The main trends of industrial automation now revolve around the following concepts:

- Smart equipment manufacturing

- Development of flexible/adaptable applications

- Predictive maintenance

- Cybersecurity

As we explained right away, the keyword here is flexibility. Therefore, all the developments should be designed with flexibility in mind.

Industrial Automation: Use Cases Where Companies Can “Skim the Cream”?

The key requirements that drive industrial automation today are flexibility, availability, predictability, and sustainability. Those who can satisfy them, explicitly gain a competitive advantage. Given this, plenty of buzzwords have entered the industrial environment, such as Artificial Intelligent, Augmented Reality, Machine Learning, Factory 4.0, and the Internet of Things, by the way. It’s important to note that the Internet of Things is a basis of a modern factory that can be combined with other technologies to maximize the benefits of each other. Here are some examples of integrated Enterprise IoT solutions which go beyond the hype and are expected to be increasingly in demand in the next ten years.

Machine Learning for QA

But did you know that a neural vision-based system for quality control can not only reduce the number of defects and soar the performance but also allow for significant savings on visual inspection solutions? Through their self-learning capabilities, neural networks process data with greater efficiency than traditional algorithms and can process the details of low-quality images. Hence, this allows for reducing requirements for industrial video cameras which are the most costly components of such solutions. Thus, this option is highly recommended to consider for your QA solution.

Real-Time Control for Raw Materials Processing

In dealing with molten metals, violation of the proportions to 0.1% can violate the functionality of the final product. Thus, when developing measuring devices for the molten metals industry, it's worth implementing IoT connectivity there to immediately provide notifications if something goes wrong since any minimal violation is critical. In addition, IoT algorithms can analyze malfunctions and identify their reason if it happens periodically.

The second crucial moment is the worker's safety in such factories. The Internet of Things offers a variety of protocols for remote access, as well as the possibility to build mesh networks for uninterrupted connection in difficult-to-reach areas. Thus, it becomes possible to set up your equipment and take samples of hot and dangerous substances remotely, as well as safely monitor your assets.

Servo Drives for Flexible Industrial Automation

Meanwhile, IoT provides an opportunity for precise analytics with the help of the tool deployed in the cloud. By building flawless ways of data transmission from “things” to the cloud, you can get a detailed analysis of which approach for processing details is the most profitable and effective. Additionally, by equipping drives and motors with special sensors, you open opportunities for predictive maintenance.

The Near Future Belongs to Cobots

Investments in the production of collaborative robots are increasing every year. These flexible and compact devices are destined for small and medium enterprises first, which present more than 90% of businesses globally. As the cobots take hold on the market, we can expect exponential growth in their production as well as a transition to becoming a must-have solution for SMEs. Thus, to capture more share of such enterprises, cobot manufacturers should utilize the best-in-class developments of the Internet of Things to make such devices faster, safer, more flexible, and, most importantly, more affordable for their users.

PCB for Industrial Automation Applications

The latter intends to implement flexible embedded systems in their manufacturing processes to easily and cost-effectively improve them during use. To achieve this level of flexibility, the solutions are recommended to be built on multi-functional PCBs with a great number of various interfaces, that are used to support IoT functionality. Thus, it becomes convenient to create a solution that perfectly fits the client production environment, and then easily add new functions to it as necessary during its operation.

In Conclusion

With the advent of the Internet of Things, Industrial Automation has stepped into a new era, where, ultimately, human participation is not expected in processes below the top management. This idea beckons lots of companies, but to get the most out of the industrial automation at this stage and lay the groundwork for increasing further automation, we recommend the following:

- Invest in industrial automation products.

- Create flexible products and build flexible systems in production that allow scaling both horizontally and vertically.

- Focus on small businesses since they have huge potential for automation.

- Actively integrate IoT solutions with other solutions that drive automation.