Steel Sampling System Updates

Highlights

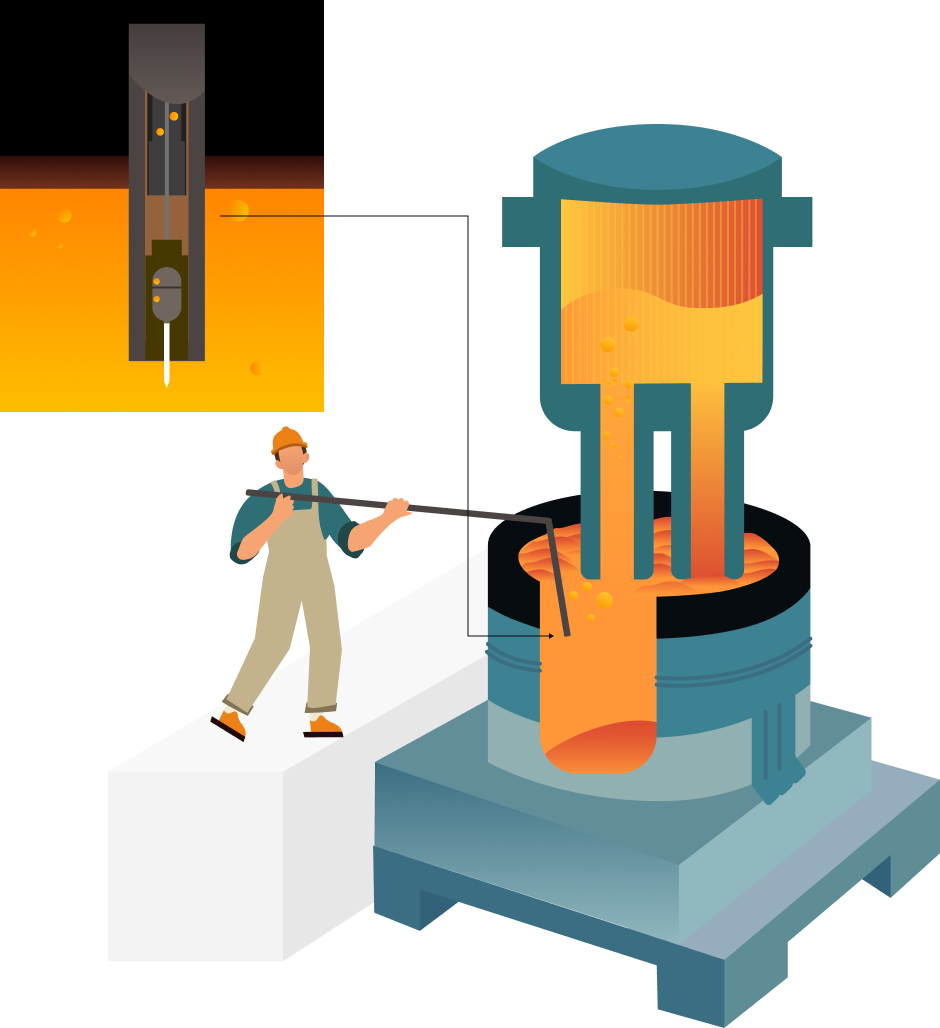

In 2018, we were contacted by a production solutions developer who intended to improve their clean steel sampling systems. The system controls the sampling of molten metal using an inert gas atmosphere. Although the system was already launched in mass production, there were some identified gaps which led to questions about the safety of the system.

Challenge

Customer Challenge

Sampling systems can’t guarantee its safe usage since it doesn’t report its status. A user is not informed about leaks, increased liquid flow, or system failures that may endanger workers and decrease the device’s performance.

Project Objective

To ensure safe and seamless usage of a steel sampling system by informing the operator about current issues.

Solution

To be informed about current status of the sampling system, it has to perform self-diagnosis that allows it to:

-

Detect leaks

-

Control the speed of liquid flow

-

Analyze the reasons of system failures

In case of an issue, the system has to allow for aborting sampling in an expeditious manner.

To realize this, we started to develop custom firmware. For the device to get updates, our team implemented a USB flash functionality support for the Logic Board, as well as the logic to update board parameters from the file on the USB flash drive or write current parameters to the file. Then, we developed a driver to perform operations with the USB flash drive. This also allows a user to analyze the reasons for the system’s failures.

To prevent injury caused by sudden increases in Flow Rate, we configured and implemented the Flow Limit, Flow Lock features and logging to USB. Flow Lock stops the system if the measured flow rate falls out of the specified range. Logging to USB shall log test settings that were in place for a measurement and record different kinds of events during measurement, like events for start/stop, pass/fail, flow rate etc.

To be sure of the tightness of the system, we implemented the Hardware Pole Leak Test setup and functionality. This test is to detect system leakage using external hardware. In addition, we changed Sampling Threshold Resolution parameters configuration to enable the user to set more accurate values.

Since the sample abort action has to be performed immediately, we made it quick and simple. All the user must do is press the start button for 5 seconds to immediately halt sampling. To alert when a steady state flow is reached, we added a chirp to the green LED.

Finally, we implemented minor firmware updates with the following features:

-

Verify all menu items and parameter limits

-

Verifying menu options according to diagrams

-

Updated logiс of switching to Sampling State

-

Engineer Testing

-

Restore the Overflow Error Menu

-

Update Flow Lock monitoring functionality

Development Included

- Requirements clarification

- Application functionality development

- Logic implementation

- Firmware updates

- Testing and debugging

Result

The updated system allows the user to identify drawbacks and can be safely utilized to optimize steel making processes.

Technology Breakdown

- 1 Technical Coordinator

- 1 Project Manager

- 1 Software Engineer

- 1 QA Engineer

- 1 Technical Writer

- August 2018 – March 2020

To deliver the solution we additionally ulitized the following technologies:

-

USB

-

FTDI Vinculum II IDE

-

Microchip MPLAB X IDE v3.61

-

XC8 v.1.42 compiler

-

Microchip PICKit 3 programmer/debugger

-

Kernel

-

VNC2 debug module

Click here to explore more technical details.