What do companies need to know before deploying the IoT Ecosystem?

That’s right, in the last 5 years the IoT market has doubled in size from $250 to $500 USD billion in North America. As demand and supply for the respective technologies grow, so does public interest and awareness. However, can every company easily distinguish between the Internet of Things and the Industrial Internet of Things? Can they exactly define what benefits they would get from implementing IIoT? Continue on as PSA sorts out the details about the Industrial Internet of Things. We will examine the layers that IIoT consists of, how it differs from IoT, and how to optimize your budget by deploying an IoT ecosystem.

What is Enterprise IoT and how does it relate to IoT?

Any device that has access to the Internet can be labeled an Internet of Things device. When you launch a Roomba from your smartphone or ask the lamp to turn the light on, even you become a part of the IoT ecosystem. The Internet of Things - is defined as a concept that links physical objects that are connected to the Internet and server. This connection makes them able to collect, store information and share it with other devices, making all the systems smarter. In fact, Internet of Things devices were created to make our routine lives easier, allowing us to spend less time communicating with various technologies.

The Enterprise Internet of Things aka EIoT is defined as a concept that implies the use of the Internet of Things at an industrial level. IIoT is being deployed on a completely different scale. The sensors can connect to manufacturing equipment, helping to detect signs of its upcoming deterioration; and take measurements, which make the operational processes faster and more accurate. Using this technology, companies of all types and sizes can make their operational processes more efficient and safe.

The Enterprise IoT solutions are widespread in various areas: from automotive and logistics to medicine and environmental protection. Indeed, thanks to the Enterprise IoT solutions, it has become more convenient to monitor working conditions in factories, track possible errors during the manufacturing processes, operate warehouses, and so on. The possibilities are endless. Just identify a current issue in the manufacturing process, and get the respective solution after implementing IIoT technologies. You can also find the term Industrial Internet of Things (IIoT) which is used as a synonym for EIoT. Regardless, both the IIoT and EIoT describe ecosystems that consist of various devices such as cameras and industrial sensors which can interact with cloud processes.

What benefits will the Enterprise get after deploying the IoT ecosystem?

By implementing Enterprise IoT solutions, the company can receive detailed information about its manufacturing processes. How efficient are they? How safe? How productive are the workers? Knowing this, the company can build an improved business strategy to become more competitive in the market.

The benefits that a particular company can get from the implementation of Enterprise IoT solutions depend on its specifics. But there are some universal ones that are associated with the ability of an IoT ecosystem to quickly collect, transmit and process the data. The most evident and interdependent benefits are:

-

Improvement of the operational efficiency

-

Optimization of the resources

-

Creation of predictable business models

-

Reduction of human and equipment costs

-

Increase of safety of working conditions

The Industrial Internet of Things gives the opportunity for companies to enhance the manufacturing processes with Smart solutions, making them faster and more accurate, hence increasing production efficiency. For instance, by improving quality control procedures with Enterprise IoT solutions based on machine vision and AI algorithms, the company’s products would be produced faster and with better quality.

With the help of EIoT, the company can rule out unforeseen situations, such as equipment downtime during the manufacturing process, ensuring high-quality resource management. If a company has lots of warehouses and needs to operate with a large number of resources, the Internet of Things gives a real opportunity to track not only their quantity but also their location, state, and environmental conditions to prevent damage. In case of the latter situation, it would be easy to find out its cause and prevent it in the future. By attaching sensors to the cargo, the possibility of its theft is minimized. The practice of implementing the Enterprise IoT solutions in vehicle fleet management is also widespread. The latter makes it possible to remotely track fuel levels, build optimal routes and analyze driving style.

By equipping machines in the factory with sensors, you can monitor their state by analyzing noise, vibrations, and more. Using Enterprise IoT solutions also helps companies to monitor energy consumption.

If your company provides the end-users with products and services, it would be much easier to collect info about the clients’ preferences and behavior. By installing sensors into the smart products, the company will get an opportunity not only to set them up remotely but also to monitor their lifecycle. It would be easier to build new business models based on customers’ preferences. As a result, companies can make more informed target advertising decisions, price adjustments, change marketing strategies, and improve management activities. Also, the use of intelligent solutions can make the company more competitive and attractive as a potential business partner.

The improvements in efficiency, resource management, and new business models can result in more cost-effective operations. By reducing time on manufacturing operations and avoiding equipment downtime, the company can save substantial amounts of money. This allows them to cut the prices down without reducing the quality of the product and, therefore, become more competitive. Additionally, the implementation of Enterprise IoT solutions leads to reduced reliance on human workers. By entrusting quality control and measurement processes to the EIoT, we make them more accurate and less costly. Basically, by having more information about business processes, and stakeholders, you can also identify negative patterns to reduce operational costs.

Increasing the safety of working conditions, which is also facilitated by the introduction of Enterprise IoT solutions, makes the Enterprise more attractive for investors, and also increases brand trust. IoT devices, which use sensors and cameras, can instantly identify danger and signal responsible people about it. IIoT also excludes the possibility of human error. In general, reducing the presence of people in the factory reduces the possibility of an accident.

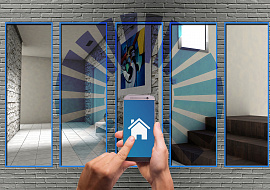

How does the IoT ecosystem work in the Enterprise?

In order to successfully implement an IoT ecosystem, the company has to understand why they need it and what it consists of. So, the IoT ecosystem consists of the following layers:

The endpoint devices such as sensors, actuators, and machines, are usually called “Things”. Therefore, throughout the article, we often refer to them as “Things”. A sensor is a small object that takes measurements of the equipment or environment, while the actuator responds by performing an intelligent reaction after getting information from the sensor. For instance, it can open the window to air premises if the sensor detects that the temperature is too hot. Such “Things” can communicate with each other as well as transfer the data to the server. Hardware and firmware for these “Things” might be both off-the-shelf and custom-made.

Different IoT devices use various wired and wireless communication technologies such as Wi-Fi, ZigBee, RFID, and the like. So, the job of the IoT ecosystem developers at this stage is to integrate “Things” to the cloud or to each other, providing non-stop data transmission.

After the data are collected from devices, they are subjected to an edge computing layer. This layer includes raw data preprocessing, caching, and buffering, which allows the actuators to perform immediate and intelligent operations. The devices that perform edge computing have more power than the “Things” themselves. They are grid powered, have different sizes, possess larger memory storage compared to “Things”, and have a better processor. At this layer, the IoT ecosystem should be provided with gateways and routers. At these three levels of the IoT ecosystem, the simplest IoT operational cycles can be performed. However, it is not enough for data analysis and building business strategies at an Enterprise scale.

Industrial controllers and on-premise servers, connected into a network at the fog layer, use large amounts of power that is not available at the edge level. Such applications can collect information from a number of edge computing devices and also allow the machines and actuators to perform intelligent reactions. They facilitate the work of information processing and storage services, as well as networking ones that interconnect end devices and data centers using cloud technologies. At this level, we can already talk about the implementation of technologies for building AI-based solutions:

-

Machine vision

-

Deep learning

-

Blockchain

The data coming from the lower levels need to be carefully stored somewhere. For this, there is a cloud layer in the Internet of Things ecosystem. Cloud storage is an IoT core, a data center with massive parallel operation capabilities, processing a large amount of data. After the analysis, you will see some patterns that will help to build a new business strategy. The cloud storage can be chosen from various IoT services, such as Amazon, Microsoft, or Google, and changed at any time. Your company may also install an internal server to collect and analyze sensitive data.

Applications provide a visual representation of data, hence allowing you to manage and control devices, i.e. “Things” such as equipment in a factory. This makes it possible for the company not only to set up the equipment and manage the factory remotely but also to track emergencies and monitor the status of the system online.

The previous 6 points mentioned above described how any IoT device works. In other words, if your company wants IoT to improve its manufacturing processes, it needs to perform the Enterprise IoT level integration. At this level, all the benefits of the Internet of Things depend on a company's business needs, making manufacturing processes and business operations smarter and more efficient, as we described above. Full cycle IoT implementation involves all the processes from the elaboration of EIoT strategy and choosing suitable solutions, to their development and validation.

Want to improve the manufacturing processes with Enterprise IoT solutions?

IIoT business advice: How to manage the IoT implementation budget reasonably?

Companies that have decided to implement the IoT ecosystem have to budget on hardware, that is the “Things”, firmware for them, and software to perform computing and data processing, as well as on establishing networks.

On the technical side, the costs of IoT implementation for an Enterprise depends on the following:

-

Types of devices

-

Number and complexity of IoT applications

-

The security level of the whole ecosystem

-

User interface requirements

-

UX complexity of IoT apps

-

Integration with operating systems and APIs

However, we certainly don’t recommend saving your budget by opting for untested Enterprise IoT solutions. The best way to avoid costly mistakes is to precisely identify your business needs with the IoT consulting services. This is why our expert team at PSA always recommends you first create a detailed IoT implementation plan. The plan should contain desired results for improving the quality of the products, manufacturing efficiency, and safety of the workplaces. It will allow the company to exclude not only unnecessary costs but also other common risks, such as security and incompatibility, mentioned in our previous article. Assess what will be better: to equip old machines with sensors and update them, or to buy new equipment and enhance its functionality with IoT. Before creating a plan, you’ll want to do the research that will assess your company’s existing assets and resources, as well as conducting a market study to identify the most in-demand solutions in that specific area.

There are some universal patterns in the IoT development market as well. For instance, it may be more affordable to buy off-the-shelf solutions than to develop your own from scratch. For starters, a complex IoT application requires the synchronization and integration of a large number of devices and security tools. It also can support GPS, an online payment system, and many other complex systems. Developing such an intricate application can cost upwards of $50,000, as Business of Apps reports. Therefore, if the situation in that particular company allows you to implement off-the-shelf solutions, it may be beneficial to do so. Likewise, it may not make sense to try and trim the budget when what you need is a custom solution. First, you’ll want to define the features your application has to support and think about APIs.

How to save money on the deployment of the IoT ecosystem?

You will definitely want to engage the right set of experts when developing and deploying your IoT ecosystem. Particularly when vetting these experts, you’ll want to ensure they have extensive experience in the EIoT area. The average IoT development team consists of a project manager, designer, at least two developers, and several QA engineers. The most common way to save money on the project teams is to outsource the project. By doing your diligence in hiring the right team upfront, you’ll save money, lost time, missed milestones, and overall headache in scrambling to correct course after a failed launch. Look for a team where you will never have to worry about the quality of the delivered project, with highly-qualified IoT specialists, such as the ones we have at PSA.

Conclusions

When looking to deploy the IoT ecosystem, companies should know the following:

-

IIoT allows the company to overview all the processes in the Enterprise at a glance and possible ways of improving their efficiency.

-

Implementing an IoT ecosystem will help you to optimize the resources, build predictable business models, reduce human and equipment costs, as well as improve safe working conditions.

-

The full IoT ecosystem consists of the following 7 layers: things layer, communication layer, edge layer, fog layer, cloud layer, apps layer, and enterprise layer. You can get a detailed report about all the processes in the Enterprise only after exploring issues of every layer.

-

Before starting an IoT ecosystem implementation, make a detailed plan, describe the goals and issues that the project has to solve.

-

You can save money and increase quality on the IoT ecosystem development by outsourcing the project. This way you will get access to the global market of top professionals, which can deliver the project at a reasonable cost and time frame.