Sensors that are installed on the dangerous equipment, or in hazardous areas, can track various parameters, such as temperature, vibration, pollution level, sounds, distance, and other parameters that are critical to providing safe working conditions.

Worker safety IoT solutions: Improving OSH while reducing costs

With their reputation in consideration first and foremost, companies tend to pay attention to issues like environmental pollution, company policy, and occupational health. You may be familiar with the debate over Amazon employees with injury rates that are nearly double the average. Amazon has since committed to reducing workplace injuries to historic lows and becoming the safest employer in the world. They will by no doubt require the use of advanced IoT monitoring technologies to accomplish this aggressive goal. Another infamous case involves Nike, which came under media scrutiny back in the 1990s and subsequently was forced to begin conducting regular audits on subcontracted factories to monitor working conditions. While Nike was, fortunately, able to create a new auditing system that gave them deeper insights and controls into outsourced facilities, the best practice is to proactively put systems and practices in place that ensure the safety of working conditions. Thus, a company can damage its reputation due to poor working conditions through a lack of control and oversight. Safety breaches result in potentially significant issues with staff, and also – potential partners. Let’s discuss how you can take steps to prevent issues before they arise and maintain full control into all of your internal and external facilities through improved IoT safety programs.

Naturally, times have changed since the Occupational Safety and Health or OSH Act was adopted in 1970 along with the founding of the Occupational Safety and Health Administration or OSHA. However, the trend is not always positive when it comes to health protection in the workplace. According to data from the Bureau of Labor Statistics, there were around 5,250 fatal injuries in the workplace in 2018 in contrast to 4,500 in 2009. While increasing automatization should have improved workplace safety, in practice, companies have not always kept pace with the technological process to maintain the required level of safety. Employees are not always well informed on how to operate the new technologies which can also cause injuries.

As you can see on the chart below, the most frequent cause of fatal cases at work is related to transportation incidents. Companies also have to pay more attention to personal relationships, staff training, dangerous materials, and monitoring the working environment.

A natural question arises here: Can Enterprise IoT solutions really improve situations with all of these factors? In fact, worker safety IoT solutions are the most suitable to cover OSH issues in 2022. This is due to the possibility of using various technologies within the IoT ecosystem and applying improved analytics to make precise predictions. How exactly? Scroll further to find out.

OSH for Manufacturing: How do worker safety IoT solutions help decrease the number of injuries?

First of all, this problem is urgent for large productions operating with complicated equipment or using potentially dangerous substances in their manufacturing processes. In general, all issues within worker safety can be separated into 2 categories:

- Caused by human mistakes

- Beyond the human control

Incidents from the first category happen when an employee doesn’t have enough information on how to operate the equipment or materials, when they are tired, or when they simply don’t notice a critical issue. The second category includes equipment breakdowns, fires, falls, and so on. Regardless, the employer takes responsibility and has to provide safe working conditions. And additional resources such as the IoT ecosystem can help with this.

Safety IoT solutions allow for launching improved monitoring across all company assets. This helps not only in detecting issues in time but also in anticipating issues before they occur. This is possible thanks to sensors integrated into the equipment that take measurements and transmit the data to the computer, as well as edge devices for performing intelligent reactions, cloud computing, analytical systems, and so on. Next, we describe how the Internet of Things helps in solving specific problems related to worker safety within manufacturing.

Hazards in plants

As you can see from the chart above, almost half of incidents are not caused by humans directly. However, falls in the warehouses, contact with hazardous equipment, explosions of harmful substances, or fires can be prevented if the company performs predictive maintenance. By utilizing the potential of IoT ecosystems, companies can perform:

.svg)

The data stored in the cloud can be analyzed after using special IoT applications. This tool can compare the data to find patterns that can help to predict when the machine is going to break. For instance, in a cafe when some strange sounds or vibrations appear, this helps issue a critical notification before the incident happens.

For an employee to be protected from enterprise incidents, they first have to be informed about the incidents in time. In the event of an incident, the IoT ecosystem can send notifications, for instance, on wearables of every employee to provide them with specific instructions depending on their location and surrounding environment.

The IoT ecosystem has a high level of automaticity that allows machines to communicate with each other to eliminate the incident. Upon receiving a notification, machines can act without an operator’s command.

Specialized sensors can operate in harsh conditions, such as high temperatures and pressure, withstand acids, and other hostile environments. For instance, they can precisely detect the distance to difficult-to-reach objects using ultrasound, detect the tiniest object using stereo-vision, or collect the data from potentially dangerous equipment.

Human status

People are the most unpredictable factor in manufacturing. However, they also should be controlled to avoid incidents. To monitor human conditions, it is handy to provide the staff with wearables – wearable devices, such as helmets, vests, or bracelets, that measure health parameters. It is especially important when components work with harmful substances, a polluted environment, or potentially hazardous equipment. It is especially relevant during the Covid pandemic. Also, by having wearables, a company can track employees’ locations to prevent them from being trapped in a dangerous area. Employees can get a notification of the event in case of some incident, such as fire, explosion, collapse, and so on. Thus, they can get personalized notifications, and leave a dangerous area faster.

To detect employees' locations as well as prevent thefts, it is also convenient to use motion sensors or cameras with a machine vision system. It helps to prevent issues like violence between staff, or even animal attacks. When a smart camera detects suspective motions, it also sends the information to the control computer and informs all responsible parties.

Transportation issues

The strategy of decreasing the number of potential transportation issues is no different from the overall manufacturing industry. However, since these are the most common causes of fatalities at work, we singled them out in a separate paragraph. By equipping the vehicle with special sensors, the company can monitor the status of every critical spare part. In any case, when a strange creak, thrust, or pressure surge is detected, the operator gets a notification showing that a component might fail soon. In that case, the vehicle won’t be allowed to participate in traffic Additionally, sensors can track the level of critical liquids and control them in real-time. Stereo vision sensors and cameras can also help detect obstacles on the way in a more precise way.

If a driver works in harsh conditions, such as extreme weather conditions, or is needed to drive for many hours, the company can “equip” them with wearables to measure health parameters, such as temperature, pressure, heartbeat, breathing, etc. If wearables track that the driver is sick or overtired, the operator immediately receives a notification to stop the activity.

How to protect office staff by utilizing worker safety IoT solutions?

Generally speaking, office work does not require as much attention to employees' conditions as factory work. However, overworking can lead to decreased workers’ productivity and can cause sickness. This has a bad influence on the whole business process. By monitoring workers’ conditions, companies can estimate a person's status to find gaps in organizing the working environment. This also helps create an optimal strategy to manage human resources.

Additionally, there is always the risk of a robbery that can endanger staff. IoT security systems in the opposite of traditional ones can utilize improved devices to detect human presence. For instance, cameras with machine vision and implemented AI analytics solutions that can identify suspective actions. Once more, it can be done using sensitive moving sensors that are installed around weak places or valuable assets. In the event of suspicious activity, they can give a command to smart locks. During a power outage, assets can be equipped with batteryless sensors that won’t stop sending actual data to the control panel.

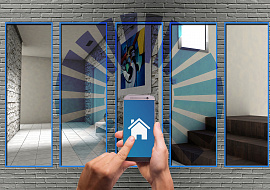

Worker safety IoT solutions Architecture

IoT ecosystems are susceptible to various technologies that allow for adapting the system to the company’s demands in worker safety. To build a reliable IoT architecture that minimizes risks within manufacturing, the enterprise should consider the following elements:

- Sensors, wearable devices, and cameras. These “things” directly measure and send the data to the computer to be processed and analyzed.

- Networks. Choosing appropriate networks would be convenient to circulate the data around the enterprise and come to interested parties. The most common protocols within the IoT ecosystem are Wi-Fi, Zigbee, and LoRaWAN.

- IoT Software. To create and implement suitable applications, a company needs to consider ERP. It is needed to implement suitable data analytical tools.

- Control Dashboard. This computer needs to receive the data, especially on alerts, and send notifications to the requested points. Use edge devices to perform immediate intelligent reactions to stop an incident.

Using this type of system eliminates the possibility of missing critical details at any stage: while collecting the data, its processing, analyzing, and finding gaps within the whole safety strategy. By having a large amount of systemized data, the company can build a robust strategy on how to improve enterprise safety.

Need help?

How do worker safety IoT solutions help reduce costs?

It may sound lofty, but IoT worker safety IoT solutions implementation really can reduce the overall company expenses. First, by performing predictive maintenance, the company saves money on fixing the breakdowns, as well as downtime expenses. The average cost of a downtime incident is about $17,000, and when it comes to automotive, downtime can cost up to $50,000 per minute. Thus, the benefits of worker safety IoT solutions for predictive maintenance are obvious at a long distance.

Second, spending on safety is nothing compared to a huge loss caused by incidents in the workplace. Reputational losses could have an impact on existing and potential partners, which could refuse to work with a company with a bad reputation. In that case, a company may take a long time to get the reputation and revenue back.

Wrapping up

In general, the IoT ecosystem contributes to worker safety. Having more information on what’s going on in the enterprise gives the company more control over workers' safety as well. In conclusion, we can identify the following key ideas:

-

Worker safety IoT solutions help prevent major safety issues, such as transportation accidents, fires, explosions, falls, violence, and so on.

-

It works by monitoring the working environment, dangerous equipment, pollution levels, and human health.

-

Before implementing any IoT solution, the company should estimate its goals and build a robust IoT architecture to cover the particular goals.

-

By implementing the IoT ecosystem reasonably, the company can not only improve the safety level within the whole enterprise but reduce expenses.