How to Ensure Reliable Communication for Rail Signaling System

From train through wayside to dispatching, the rail data is transferred around the signaling system to perform its core objective – to ensure the safety of the trains' movement. Since continuous communication is the indispensable condition for signaling to fulfill its function, any communication error is critical for it and induces signaling failure. Even though failures are safe, the delays also lead to economic losses.

Although more options exist today to provide seamless communication in the digital age, new communication challenges appear as well. More systems potentially need to be connected, more specific conditions are required for wireless connections, and more strict demands for high-speed trains – these bottlenecks significantly slow down rail projects. You’ve probably heard that some rail companies remove modern PTC or ETCS systems after several years of operating due to incompatibility issues. Not the brightest prospect, is it? That’s why we’re sharing a piece of our 15-year expertise on rail signaling solutions showcasing how to ensure rail network reliability. We’ll go on to clarify whether signaling engineering should quickly adopt to digitalization to make the railroad compatible, and how to strike a balance in pragmatism, productivity, and safety of the railroad.

What Needs to be Connected within the Rail Signaling System?

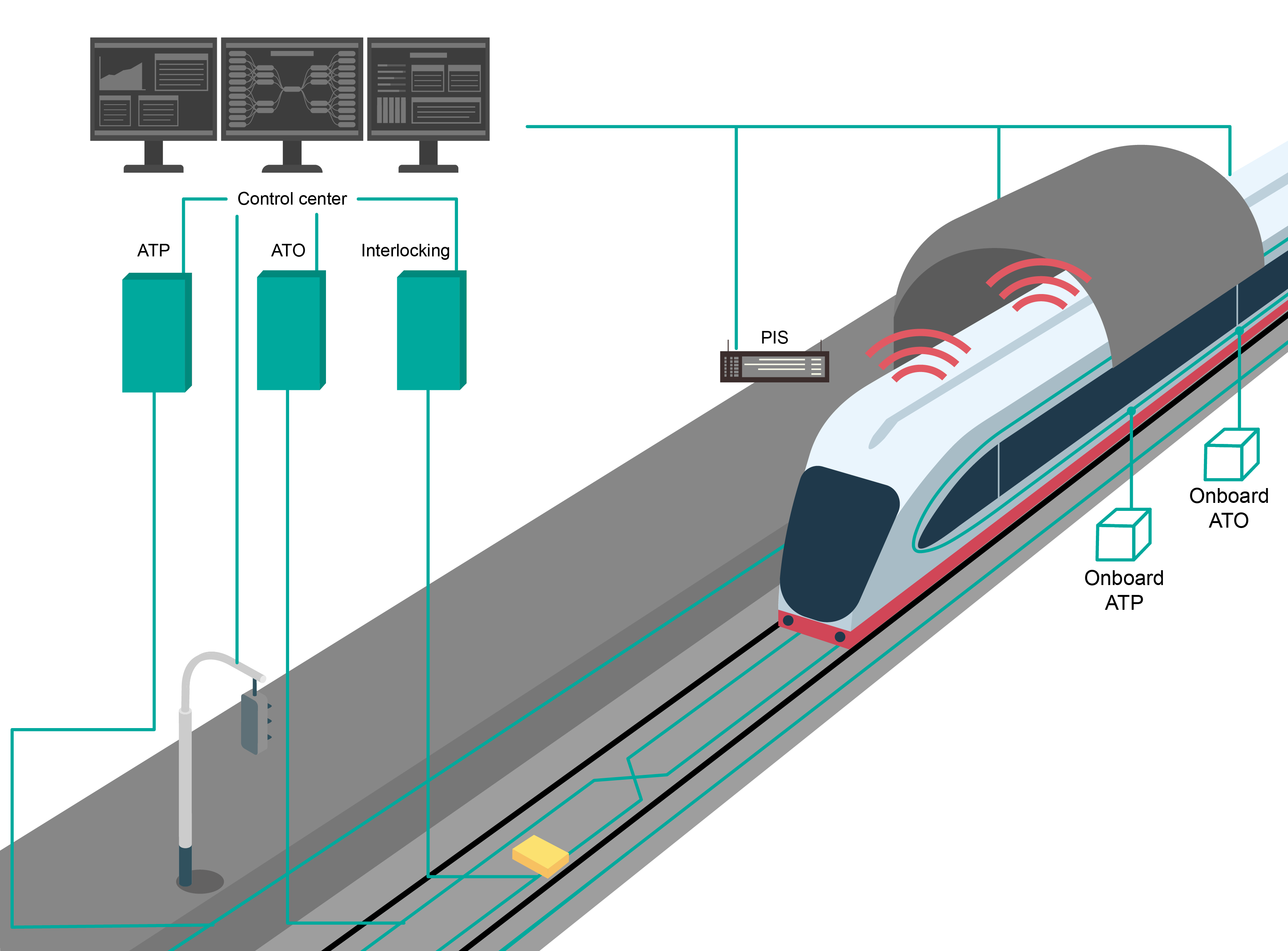

To ensure the safety of the train movement, all the units that participate in it have to be informed about train location, direction, and speed. Such safety measures as train separation, collision avoidance, line speed enforcement, temporary restrictions, and rail wayside safety depend on the timely transmission of the train data and require robust and integrated network infrastructure. In general, communications should be established between:

Despite the need for rail signaling system to reliably connect all the rail units in different variations as we described in the picture above, the most complicated and responsible task is to establish seamless contact between train, interlocking, and wayside equipment. This core communication allows the system to open and close signals. The two issues which can be identified here – are how to continuously get the data from the field, and how to manage it on the field, for instance, throw the switch. Much depends on the type of signaling equipment. We’ve already discussed when it is better to upgrade the rail line with digital microprocessor systems, and where we can utilize analog relay-based systems. Although both of these systems are fast enough to provide a high level of capacity for passenger and cargo transportation on all the railroads, except metros, various connectivity issues might force a system to fail. Read on as we show you how the well-designed connectivity architecture can decrease signaling failures and corresponding losses.

What to Consider When Organizing Communications within the Rail Signaling System?

Connectivity in signaling – is not only the type of connections but the way of organizing the signaling infrastructure. How centralized the rail signaling system is, how many links it contains, the scale of the station, and environmental conditions nearby – we consider all these factors to build robust connections within the network. Experienced signaling engineers ensure the interroration cycle of the wayside controller is less than 1 second. The other main key – is to monitor solutions in the rail and IT market. Due to extensive digitalization, the new boards, modules, control applications, and other software and hardware that might be useful for rail, constantly appear on the market.

The main activity for building signaling infrastructure is picking up connectivity methods and considering wired and wireless connections in the field. Basically, wireless connectivity is faster, but wired connectivity is still considered the most reliable way to exchange data between wayside devices and moving trains. Let's go deeper.

Wired Connection

Is there still a need for wires on the modern rail lines? At least, when upgrading the station, a need may appear in leaving legacy logic partially which means utilizing wired connectivity. In modern systems, we can use fiber optic cables to get the train data from the field and send it there, and Ethernet to connect wayside controllers on the extensive station. Regardless, the major issue interrupting wired communication is its aging or physical damage through environmental conditions.

How do you protect devices from environmental damage?

One of the major issues comes with its need to be fully operable in harsh environmental conditions, such as snow, ice, high temperatures and humidity, and so on. Despite the fact that signaling equipment needs to be designed, on average, to be 10 times more effective than one implemented with commercial devices, it still suffers from the factors mentioned above which cause failures. General schedule maintenance can’t provide continuous monitoring of signaling devices. To increase reliability, companies can utilize Enterprise IoT solutions with advanced data analytics and predict possible issues before they lead to failure. This resolves the various issues of designing the data transmission network and ensures the overall reliability and efficiency of systems serving critical infrastructure.

Wireless Connection

Surely, the wireless connection has much more potential than wired, such as speed, ability to transfer data to various units, and more devices to be connected simultaneously. Basically, various wireless protocols, like radio-based, GSM-R, or other industrial connectivity solutions, suffer from very similar issues. They all need towers to transfer signals and are affected by obstacles. Below we clarify what to consider while establishing wireless communication.

How do you Overcome Constructure Issues?

Hardly any rail line can be designed without bridges and tunnels. The latter can induce connectivity issues due to construction interrupting a signal. However, this issue can be well-calculated at the design stage. A need might appear in using additional radio towers located closer to each other, or additional transponders on stations to ensure full-time control. Directional antennas, feeder "leakage" transmission, or radiating feeder cables can also be useful in providing seamless connections in the tunnels. There are many connectivity solutions in general and the main task for engineers here is to combine them in the most productive way for a particular track or station.

Considering Signal Issues

The main environmental reasons why the signal can’t be delivered physically are electromagnetic interference, weak signal, or saturation of the communication environment. Since the signaling equipment and interlockings are located onsite, any storm can induce interference. Also, it faces technogenic factors, such as accidents on power lines, or switching powerful devices. Regardless, these issues have to be better predicted and solved at the design stage by identifying ways of reducing interference. For instance, we recommend using a shield with high electrical and magnetic conductivity to attenuate electromagnetic interference. On one occassion we needed to replace the commonly used wayside controller with the other one since the electric power lines were too close.

The saturation of the communication environment is an urgent problem for some protocols, such as GMS-R that is used within ETCS. The risk of mixing frequencies with the LTE range is possible because their frequency bands are very close. As a result, there is a growing trend toward monitoring and managing GSM-R interference using active and automated testing on board trains and on the side of the track.

Cybersecurity

Data breaches can happen regardless of the type of system because all the data transfers to dispatching anyway. Since cyberattacks are becoming more frequent and sophisticated in recent times, the rail industry should be protected from them especially carefully. Surely, modern microprocessor-based rail signaling systems are highly protected against cyberattacks, but this protection needs to be improved permanently. For instance, during PTC system implementation, you should always take precautions regarding the custom key management system to allow the train and wayside to communicate securely.

How do you overcome compatibility issues when upgrading a rail signaling system?

Compatibility is a really sensitive spot when you need to connect equipment that operates within different systems. We face fewer issues when combining legacy relay-based with digital microprocessor-based systems, of the flexibility of applying the logic. The real headache comes with matching various microprocessor systems, generally, a legacy with a cutting-edge. It happens due to communication protocol obsolescence, which is why designers need to find ways to update one or both systems to enable reliable communication. Additional dedicated transmission modules (STM) for interfacing with legacy signaling systems can be utilized there. In one case, we developed a custom memory solution for the microprocessor-based system to replace an outdated memory module to ensure the communication of the whole rail signaling system.

If the connectivity between the system’s components fails suddenly, it may lead to a failure, like when the gate doesn’t come down in the crossing. We’ve witnessed these situations several times, but they can be prevented with more attention paid to connectivity. Also, predictive maintenance might help here, which we previously discussed in another recent article.

Need help?

What if a Failure in the Rail Signaling System Already Happened?

Since all the possible connectivity interruptions have to be solved at the design stage, we won’t dwell on this point. It’s clear that the fault cable has to be removed while failures of wireless connections are temporary if the rail signaling system is designed properly. The main issue comes from a connectivity fault within the wayside controller.

To ensure that failure does not cause long delays, we need to have the possibility to restart it immediately in a safe manner. To ensure, it’s necessary to perform backups when designing the rail signaling system. In a decentralized station system, microprocessor units can operate simultaneously which allows the alternate unit to start operating when the main fails. Another scenario implies launching an alternate unit after the main fails. It requires more time to start, get the info, and continue operating. This is the advantage of decentralized systems because if the centralized system fails, the whole station might stop before the issue can be identified. This moment should be performed automatically because humans at this stage cause most of the train delays.

There is one more reason to save the analog rail signaling system while updating the rail line. The legacy system can act as a reserve to communication failure so as not to force the whole system to fail.

Wrapping up

There are no impossible missions in signaling. But connectivity missions resemble designer collections where not all the details are necessary and suitable for each other. The main task is to find the most affordable and performative way to do it.

-

To increase the resilience of the rail signaling system, possible compatibility issues have to be predicted and solved at the design stage.

-

The main connectivity task is to provide communication on the field promptly. The type of connectivity should be chosen individually and depend on the equipment and environmental conditions.

-

Predictive maintenance solutions are reliable in predicting any sudden breakdown of the signaling equipment.

-

If the system fails, it is necessary to improve backup processes and make them automatic.

The rail market is closed enough to observe all the issues that companies face. However, with experienced engineers as part of your outsourced team, a company can sure seamless connectivity within the delivered signaling system. PSA is welcome to design the rail signaling system both for modern and legacy lines, considering all the incompatibility issues.