Rail Software for Signaling System Design

The same goes for dispatching CBTC systems, analytical software for predictive maintenance, or simulating tools for designing rail lines in view of specific environments. However, since rail projects already require drawing on lots of resources, it becomes hard to justify additional costs, especially on tools for design and simulation that makes the latter less enlightened among others. But is it really reasonable?

Today, rail software for signaling system design can be developed in extreme detail and simulate both station architecture, and specific functions for the wayside controller. These “advanced simulations” can forecast signaling failures before exploitation of the rail line starts which is not always possible through analytical tools for predictive maintenance. Being a signaling engineering company, PSA develops and supports signaling systems after their launch in the field. Thus, we know the most unsafe and costly signaling failures, which could be already prevented at the design stage if we pay more attention to the design and simulation tools. In light of this, we want to dive into rail software for the signaling system design to help realize when it’s really worth being “intelligent” before the rail line runs than working harder while it runs.

What Can Be Simulated with the Railway Software?

In the digital age, what we can say about simulations – is that everything can be simulated. A need for detailed simulations for the signaling system is driven by two factors: various equipment that needs to be compatible, and a custom signaling architecture for every specific location. For instance, we can check if particular components of a legacy system are compatible with particular components of CBTC, PTC, or ETCS infrastructure. We can try various options to pick up fallback components if required, as well as simulate signaling failures. It is especially essential for decentralized systems on large rail stations where 100+ signaling units need to be coordinated.

Therefore, to run various possible what-if rail transportation scenarios, rail software needs to simulate various operations, such as:

-

Interlocking functions and train movements through interlockings

-

Train detection between blocks

-

Temporary speed restrictions

-

Maintaining the connections while trains move

-

Crossings control

Thus, the simulator that responds to all the possible inputs help identify design drawbacks at the beginning of the development lifecycle. The design tool that includes all these operations performs some sort of testing long before Factory Acceptance and Site Acceptance testing. In the field, we validate that signaling hardware and rail software can operate correctly in specified conditions. The system’s behavior in extraordinary situations or with new custom components can be calculated at the design stage. This is especially essential when it comes to developing subsystems that manage wayside devices. Before connecting the new board with the central controller, it’s worth simulating it in a safe environment to identify the components that might fail. Thus, the full simulation is a great thing about paying special attention to the system’s hardware and software which reduces the probability of them being modified after running the rail line.

The essential advantage of the reliable rail simulation environment – is its adaptability. It should perform design considering the scenarios above, for both a low-speed track section with one locomotive in an hour or a cutting-edge CBTC system for high-capacity metro.

How Does a Reliable Railway Software Look Like?

Until railroads are not universal around the world or at least over one continent, simulation exacerbates the need for custom tools development. Thus, the rail simulation environment also implies specific equipment to recreate all the features of the wayside controller. This helps consider the impact of all its modules, communication protocols, and architecture features to precisely simulate all the components we mentioned above.

To have an opportunity to match simulated field devices with the central controlling unit we need a specific industrial-grade computer with specific rail software integrated. Various components can be simulated there, such as:

- The wayside controlling unit

- Source code of the controller and signaling units

- MCU and relay logic

- General-purpose cardfiles

- Ethernet communication boards

- Location-specific software and I/O components

In this way, track circuits, railroad switches, interlockings, and other rail devices can be precisely recreated considering their specific logic. We can find out, for instance, how the environmental and weather conditions influence the reliability of the track circuits, or if communication slows down due to the outdated components. This reduces chances to fix signaling errors in the future. Therefore, when designing the signaling system for a rail line with the help of custom tools, companies can expect to see some savings on maintenance.

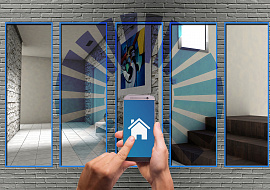

To have a complete view of the future rail line, we recommend developing source code for the wayside-controlling apps, testing functional characteristics for the interlockings, and simulating the behavior of field devices in real-time. Having such a precise simulation, we almost have a digital twin that can continue to forecast the system’s behavior and issues in real-time. Having precise visualization, the company widens the potential participation in the rail project. When showing how the particular device impacts the rail’s capacity to the customer, they can make crucial decisions on the project faster.

What Issues Can Railway Software Help Prevent at the Signaling Design Stage?

Since the main issue of the signaling systems is their frequent failures, which can also be unsafe, we want to emphasize how these failures can be prevented through detailed simulation at the design stage. We’ve already discussed IoT predictive maintenance for rail transportation that plays a really significant role in decreasing signaling failures by mitigating exploitation risks. At the design stage, you can simulate equipment or code failures, incompatibility issues, location specifics which can induce signaling failures. Types of communication, centralization, or environmental conditions – everything can be duplicated for the rail signaling software when designing the system.

The probability of a signaling failure increases when connecting new equipment with the old equipment. For instance, any outdated memory card can meet incompatibility issues when adding new elements to the wayside controller. If you decide to leave some outdated components when upgrading the rail line, it is advisable to check how these components behave with various systems, and if they support various communication protocols allowable within rail scenarios.

There are some typical, but problematic scenarios which are advisable to consider at the design stage of signaling equipment, such as:

- Loss of communication

- Field device failures

- Wayside operating mode changes

- Meet-pass and siding operations for the freight railroad

In addition to interconnection issues, environmental conditions should be also taken into account since they can cause failures. When it’s a risk of communication dead zones, or the power plant located nearby go unnoticed, the project might be amended in the later stages.

There are plenty of similar scenarios where the signaling system goes to safe failure. In addition, to prevent failure scenarios, the design tool can help verify the safety of the failure, and the fast restart after it. As a result, you are likely to get the system to run quicker to be compliant with safety.

Conclusions

To comply with the safety and meet the budget of rail projects it is essential to strike the “intelligence” balance and decide on digital tools: either improve predictive maintenance or provide funds for designing the signaling system. When you are looking for advanced design tools, remember the following:

-

A reliable signaling design tool has to be custom to consider all the features of the rail project.

-

While utilizing rail software for designing and simulating the signaling system, consider hardware logic, source code, specific boards and components, and communication protocols.

-

The most beneficial such system is for the large rail stations with decentralized signaling systems.

-

The essential thing is to try various devices, components and communication protocols, both new and legacy.

Such tools help you deliver the project faster and give more potential for future use. PSA is experienced in delivering custom design and simulation tools that increase safety on the railroads. Thus, we invite you to become “intelligent” during the design phase so as not to work harder when the line runs.