As improved navigation systems, tools within the IoT ecosystem can get and display the info about weather, traffic situations, accidents, and so on. At the same time, they have the data about previous routes, vehicle health, and driving style, and can create the optimal route considering maximum parameters. All parameters can be monitored in real-time.

IoT in Logistics: How to streamline supply chain management

Although the logistic sector has a long history of using various supporting tools, there is still room for growth in simplifying transportation processes. This is especially noticeable now with increasing demand due to developing e-commerce and a considerable rise in bilateral trade activities in North America. Now we notice smooth growth in the logistic market in the USA that reaches $1,089 Billion in 2022. Even Covid-19 and a global crisis provoked only accelerated growth in the logistics market, due to significant need to urgently transport essential goods over the country.

.svg)

Today, the IoT in logistics can help make the most accurate predictions on traffic, avoid delays and injuries on the road, as well as make the processes more transparent for clients. So, an IoT tool can simplify some parts of the logistic operations, but by implementing an IoT ecosystem within logistics, companies can see the whole picture of the processes, capture critical data about the fleet and cargo, and then study every chain of the system under a microscope. By making a business strategy based on the received data, both product companies that manage their transportation and logistic companies can become more attractive to the potential customers while reducing extensive costs. This makes IoT solutions for logistics not a simple trend, but a real troubleshooter. In this article, PSA outlines how it comes.

A quick look at the capabilities of IoT in Logistics

Internet of Things solutions technically imply sensors to collect the data from the physical objects – vehicles, equipment, and others; platforms, usually cloud, to data be stored and analyzed, and networks to provide reliable connections. The Enterprise IoT can track any equipment, staff, and security issues, detecting deteriorations and improving processes. Regarding logistics, there are 3 important factors that can be monitored by IoT solutions – cargo, vehicles, and staff. Some systems such as vehicle navigation can act like active assets within the IoT ecosystem and transmit data to the cloud without additional actions. Others such as cargo or vehicle spare parts don’t have installed computers and can act like passive assets and should be equipped with sensors to transmit the data.

Cargo equipped with sensors can be easily tracked by having all the current info about it. It also eases loading, unloading, and receiving cargo. Environmental sensors can monitor the conditions of the warehouses. By equipping vehicles with sensors, a company can track vibrations, sounds, and liquid levels as well as its specific environment.

Digital platforms provide storage for the data collected from the sensors and other connected systems. Since they are designed on open source systems and a microservices architectural approach, they can adapt to changing load profiles. IoT software here allows to process and analyze all the collected data.

Networks here provide all the connections between “things” equipped with sensors, between IoT layers, to the cloud. Depending on the type of an IoT ecosystem, the company can choose various communication protocols, such as Wi-Fi, BLE, ZigBee, RFID, LoRaWAN, and so on.

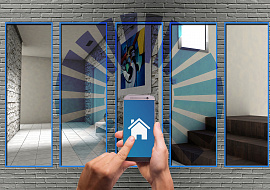

Off-the-shelf and custom IoT applications provide user experience here. With these tools, companies can see analytical reports based on collected data, as well as see and control all the processes within the ecosystem online.

Urgent logistics issues: how can we overcome them thanks to IoT?

The main issue here is complicated management due to the inflexibility of the logistics industry. Since the distinctive and most important feature of logistics is the supply chain, IoT solutions are aimed to structure and simplify supply chain management. At the same time, various related issues arise, connected with transportation delays and cargo storage. Eventually, the question arises: How does the logistics company explain all the delays to their client when so many circumstances occur that are outside of their control?

Transportation issues and use cases

Since intermodal freight traffic is the widespread choice to move light freight, the result is more challenges for logistics companies. In general, trucks stay the most in-demand mode for freight transportation, according to the U.S. Bureau of Transportation and Statistics. This greatly contributes to the development of IoT in logistics, since the trucks are susceptible to IoT solutions.

Major issues for transportation within logistics are:

A vehicle equipped with a scope of sensors can transmit data about the health of its various spare parts. For instance, untypical vibrations or sounds detected by sensors can highlight weak points showing a breakdown that might come soon. Likewise, aggressive driving styles can be detected. Also, there are specific IoT multi-measuring sensors that will help to get more critical information. Thus, the company realizes predictive maintenance of all the fleet, saving on repairs and delaying expenses.

It is yet the most expensive link in the whole supply chain. Delivery tracking is basically a manual process that involves people at every checkpoint to collect data. Surely, the Internet of Things is hardly influenced by it, but by tracking accurately it is faster to find appropriate cargo. In the near future when drone delivery will be widespread, drones can be easily connected to the cargo in the IoT ecosystem and do all the jobs automatically.

Surely, IoT in logistics can’t impact fuel costs, but it can help in monitoring resources. By installing sensors, the company can track how the driver uses the fuel. Creating the optimized roots also helps to spend less fuel by considering all the possible parameters.

All this will help a company to avoid transportation delays and customers’ complaints as a result.

Warehousing issues and use cases

Warehousing issues differ from the types of cargo that are stored and transported. In North America, the most frequent freight to be transported is manufacturing equipment, consumer goods, retail, food and beverages, IT hardware, healthcare cargo, and chemicals. As we can see, a majority of such cargo requires special conditions of storing. When it comes to manufacturing – the largest sector within logistics in North America – companies often transport unique expensive equipment or its parts. To protect it from damage, loss, or theft, IoT sensors can detect abnormalities, and send appropriate notification to the operator. The same attaches to IT hardware. Food, beverages, chemicals, and healthcare goods often require special storing conditions such as set temperature, humidity, etc. Sensors can detect if some parameters are beyond the norm, and send a notification to the computer showing that some parameters have to be changed. Within the IoT ecosystem, such operations can be automated thanks to edge computing. When the edge device gets the info, for instance, that the temperature is too high for a particular product, it can send a signal to the actuator to change the temperature.

By picking up appropriate IoT solutions the company can solve the issues connected with:

-

Storage

-

Sorting

-

Acceptance and Shipment

For monitoring the cargo and having all the current data on the cargo on tap, it is convenient to use, for instance, RFID tags. They send the data directly to the computer, do not need to be scanned, and withstand harsh environmental conditions. Thus, it becomes easy to track the location of the particular freight and set appropriate conditions, which also simplifies operations at the stage of cargo acceptance. It becomes easier to match product codes, sort products, and detect their shortages. To be sure that the cargo gets to the end-user without issues it is also convenient to use RFID tags and GPS sensors within the IoT ecosystem.

For the valuable cargo, it might be beneficial to implement an IoT warehouse security system. Special sensors or connected cameras with a machine vision system implemented can detect suspective motions inside or around the warehouses. Tracking automatically means an improved degree of security because the company can monitor assets in real-time to prevent thieves.

Enterprise IoT solutions are also helpful when it comes to warehouse robotization. When an autonomous mobile robot gets all the info on the cargo, it can perform all the activities itself from receiving information on what to take, finding the required cargo, and moving all stuff to the destination point.

IoT in Logistics to improve customer service

Since it is not always easy to explain to customers why the cargo is delayed, it leads to lost trust. However, when there are plenty of issues within logistics that are not under the control of logistic companies, the management needs to set up a reliable communication system to provide clients with all incoming information regarding their cargo. For instance, there are many unpredictable traffic errors, invoice errors, and analog follow-ups which complicate the tracking of freight. IoT in logistics can help to show the full supply chain and connected processes in a very transparent way that allows. By sharing access to the application, the client can see what happens in real-time, the status of delivery, and environmental conditions in the warehouse; get notifications on their smartphone, and take some actions online. Thus, they can track the shipment from start to finish without requesting a status update. Blockchain technologies can be also used here. Blockchain storage ensures that participants in the distribution process cannot subsequently change the necessary data, for example, to prove that a transport task was properly performed in their interest.

How Сan the Use of IoT in Logistics benefit the Analytics Processes?

Any case described above simplifies a part of logistics management: improved tracking systems provide visibility and strengthen monitoring of the assets, edge, and cloud computing increases automaticity while reducing human mistakes. However, by being a part of the IoT Ecosystem, these solutions can gradually impact businesses by giving urgent information on how to improve it. The IoT Ecosystem tools can:

-

Collect the data from all connected sources

-

Provide handy storage of a large amount of data

-

Analyze the data to find gaps and patterns

-

Make reports in a convenient representation

Typically, any logistics company produces a huge amount of data per day, so it can be used as an instrument to improve a business strategy. It is possible thanks to cloud platforms within IoT software. Analyzed Information can be provided to the other participants in logistic process systems through interfaces based on established web standards such as Representational State Transfer (REST) and JavaScript Object Notation (JSON).

Summarizing the aforementioned, it can reduce costs on maintenance, fix human mistakes, create the optimal routes, save on staff, and so on. Companies can compare the cost of shipping options from different locations, take into account the payload of vehicles, or which items must be collected at the same time to meet the SLA. Having more info about the transportation, delivery processes, and client, it becomes more clear the critical points to be improved. By processing more data, businesses can determine the best transport and routes, reduce carbon emissions, and improve the quality of service for their customers.

Wrapping up

After all, logistics is not a flexible area. However, by implementing an IoT ecosystem a logistics company can build a reliable strategy for improving transportation processes, and:

-

Reduce costs on maintaining the vehicle fleet by predictive maintenance

-

Reach higher quality by cargo tracking and quality storying

-

Improve business models by identifying bottlenecks

-

Reduce the number of complaints by offering transparent processes

PSA outlined all the major cases of the IoT within logistics for improving the business processes. By detailed assessment of your company’s business needs, we can determine what cases are likely to be implemented and deliver the IoT ecosystem. There might come a critical point soon that will make it impossible to develop logistics without IoT solutions. It is better to be prepared, right?