How Much You Can Save through Predictive Maintenance

As the saying goes, you can’t hit the target you can’t see. It ultimately reflects the core issue of preventive maintenance. By performing a fixed set of procedures after a certain time we go with random chance and can’t eliminate risks of downtimes. On the other hand, Predictive Maintenance allows for setting the sights on the vulnerable components of equipment and vehicles, as well as stopping to fire blanks during maintenance. Such targeted maintenance significantly accelerates the maintenance process and decreases downtimes, which brings great savings for an enterprise. But how to try it on your business?

As we can see in various statistical reports, the cost-effectiveness of predictive maintenance is consistently high, from 12 to 25% according to different sources. These are certainly pleasant numbers, but it needs a more meticulous calculation to have a comprehensive view of its custom benefits for your enterprise. Let’s find out what is behind predictive maintenance as IoT solution for enterprises, how much you really waste through downtimes, and how fast the investment will pay back.

What is Predictive Maintenance?

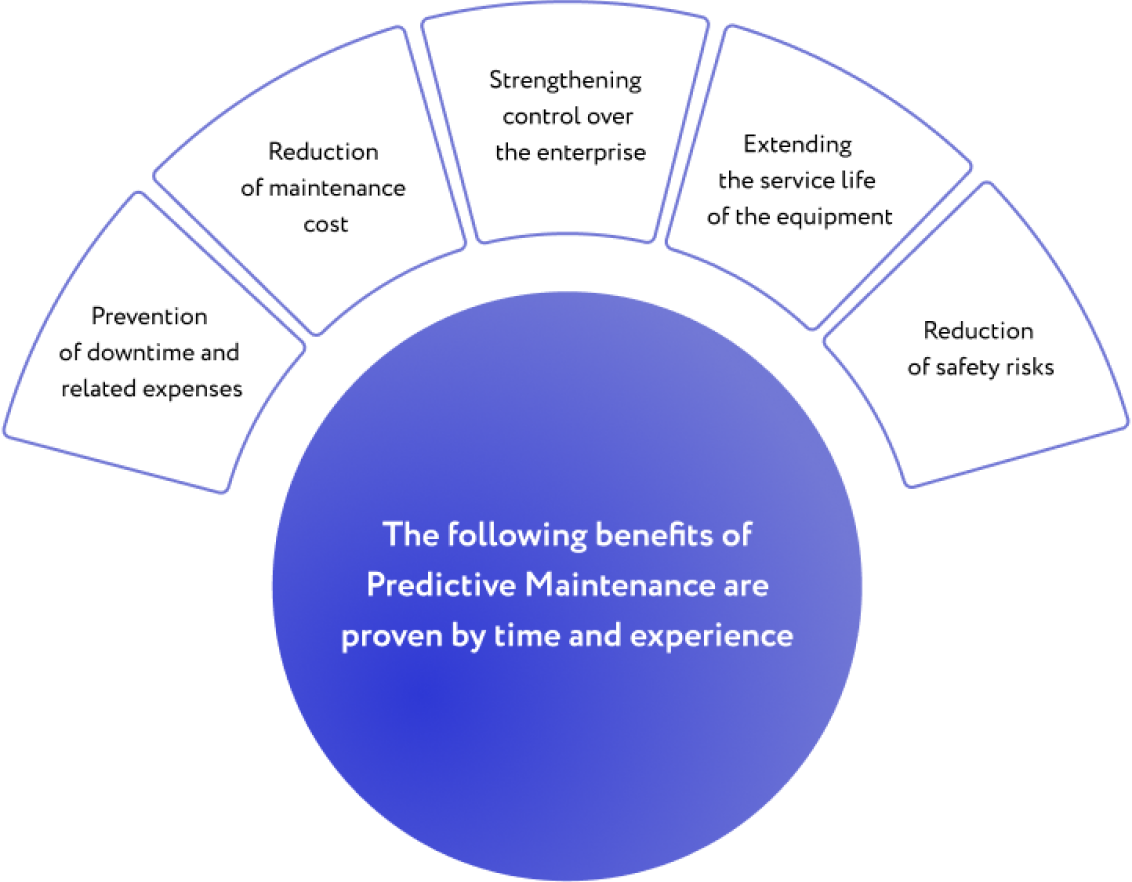

Predictive Maintenance (PdM) - is defined as a practice of planning the maintenance of equipment exactly when it’s necessary, and only for the equipment that needs this, thanks to non-stop monitoring, analyzing, and reporting the state of its components. This is a self-sufficient method, however, it is the Internet of Things that caused its breakthrough and widespread implementation globally, by simplifying data collection, analytics, and the use of applications.

Moreover, Predictive Maintenance only gains momentum – sensors are becoming more diverse, sensitive, and affordable; Networks are becoming more available; and algorithms are growing more complex, which allows you to clarify predictions and add new forecast parameters. This is striking that by involving more data in IoT analytics, the system becomes only more accurate and useful. All it needs is what you have – your custom data!

The size of benefits on those items can significantly differ from company to company. To gain perspective on it for your business, it is worth considering all your data connected with downtimes and maintenance.

Who Might Benefit from Predictive Maintenance

The production environment of each company is a unique organism that will never adjust to standard recommendations. However, you have all chances to succeed with Predictive Maintenance if your business is connected with:

To increase the savings of Predictive Maintenance in manufacturing, it is recommended to implement it for critical assets in production workshops and in quality control departments. Information you gain through Predictive Maintenance is valuable for various departments. For instance, it helps in the procurement of components, as well as for executives to adjust business strategies.

The most common applications for vehicle health control are tracking engine performance, exhaust systems, transmission functions, and structural stability. Information obtained during the analysis of the vehicle data can drive high-level decisions. For example, you will know the details of which manufacturers are reliable or hold a conversation with the driver if their driving style is too aggressive.

Predictive Maintenance: Success implementation Factors

The success of PdM for the enterprise, that is, the savings from its implementation, is the balance of several factors. First, is the accuracy of calculations on possible savings of Predictive Maintenance for your business. It might happen that your investments in PdM solutions would not return at all since downtimes don’t affect your production significantly. That’s why at the estimation stage you must clarify if your company needs PdM. If you need alternative methods, we can suggest other EIoT solutions that will make sense to improve productivity.

The second essential factor is how widely Predictive Maintenance is planned to be deployed in your enterprise. If preserving preventive maintenance for most of your assets, you postpone the moment your investments return, or destroy them. On the other hand, the mass implementation can be simply needless for your equipment.

You should also pay attention to the technical execution of the PdM solution. All IoT ecosystem components must suit to your production environment; sensors to withstand your production conditions, and networks to be reliable. You need to decide the way data collection is going to be organized. The most common approaches are:

- Vibration. Track the frequency and power of components' vibrations is preferable for equipment with high rotation frequencies. It is used to detect an imbalance, misalignment, deterioration, mechanical weakness, and backlash of the equipment items. This method is the most common way of data collection, and therefore the most affordable.

- Infrared. Thermal cameras allow for tracking insignificant changes in temperature that is critical for example, electrical and power equipment, as well as for construction audits. It allows for the detection of the components' wear, chemical contamination, corrosion, fatigue, and faulty assembly in many electrical systems.

- Sound and ultrasonic. Atypical noises and volume fluctuations might indicate quick deterioration, misalignment, looseness, and lack of lubrication for the equipment components. The point is that sound monitoring helps detect anomalies earlier than vibration or temperature monitoring. Meanwhile, the high-frequency sound waves are tracked to detect leaks, parts warpage, and cavitation.

- Oil analysis. The oil is usually tested on viscosity, water presence, iron content, dielectric strength, and many more. Thanks to fluid analysis it is possible to detect wear, overheating, contamination, or corrosion.

The more complicated the equipment is, the more components can fail, and the more monitoring parameters can be configured. Multi-function sensors seem to be created for such cases, but it can also be valuable to strengthen processing and analytical tools instead. For example, when tracking sharp cornering, excessive acceleration, and hard braking during vehicle motion, you can use only a gyroscope without an accelerometer, but it requires much more complex algorithms to get the full data.

Predictive Maintenance: Calculating Cost Savings and Accelerating ROI

Do you know how much you really spend on equipment maintenance? How much is wasted through downtimes? To calculate the benefits most accurately, you need to face these facts and dig the statistics up. To check whether the investments for the PdM solution will repel for the year, and calculate the expected savings, you should have all the information on maintenance you usually hold for this period. We propose the following formula:

%201.png)

This formula is advantageous to be customized for various cases within your business environment. For example, you can separately calculate the downtime costs for equipment and transport, consider safety risks, and include the worst and best-case scenarios in the calculations.

Don’t forget to consider related values. Statistics show that:

- PdM increases asset availability by 10% on average reduces maintenance costs.

- Equipment lifespan extends by 20% on average that brings about a reduction of capital costs.

Although this value can’t be calculated, you can estimate it. The newer equipment you have, the higher value you can get for these points.

Predictive Maintenance: How You Can Replace It

If you agree with the above points but are not yet ready to deploy scalable Predictive Maintenance at your enterprise, there is a nice alternative – Condition-Based Monitoring and Maintenance. It does not involve a high-level function of in-depth analytics of the data collected, as opposed to Predictive Maintenance. However, it also allows you to efficiently monitor the equipment and get alarm notifications in real-time, which means the opportunity to hold more informed maintenance and discover issues before it leads to downtime. All data collection methods described for Predictive Maintenance are also relevant for condition-based maintenance.

In addition, condition-based monitoring is an excellent aid if you decide to introduce PdM in the future. In that case, you will already have a database that contains information on the most vulnerable components of your equipment, the frequency of issues appearing, and predicted and unpredicted downtimes. This will help you to create or implement the most effective algorithms to analyze your big amount of data and will provide you with the first forecasts faster and more accurately.

Tips for PdM Implementation

- The success of Predictive Maintenance comes from the accuracy of efficiency calculations, the scale of PdM integration, and the technical execution of the solution.

- Savings estimations should be based on the enterprise data, not on external sources.

- At first, you can introduce PdM only for critical assets but envisage its scalability.

- There is an option to implement PdM step-by-step starting from condition-based monitoring that provides you with information on equipment status in real-time.