Built-in AI for Defect Detection Device

Highlights

A startup focusing on Machine Learning-based products has collaborated with PSA in the field of production defect detection. Following the successful delivery of the Machine Vision QC System to the printing client, we proceeded to jointly enhance this product before market launch. We focused on the reduction of deployment and mounting efforts, as well as efficiency increase, by putting all the AI computing into the device to support plug-and-play implementation.

Challenge

Client Challenge

Assess the possibility and feasibility of creating a more capacious and efficient QC product for plug-and-play implementation without server AI deployment.

Project Objective

Check the possibility of the current Machine Vision System to perform AI computing within a device. Provide redesign efforts estimation.

Solution

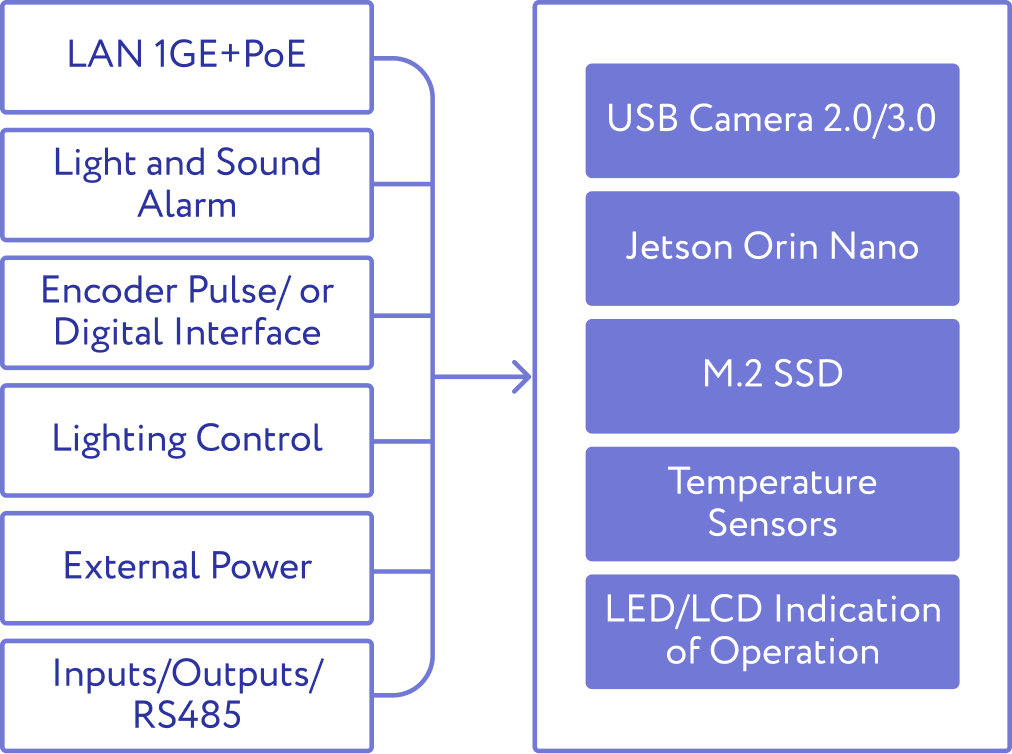

For the system to support real-time AI-based defect detection within a device, it required a more capacious hardware platform. We selected the Nvidia Jetson board as a performative and cost-effective solution as it maintained all the prescribed functionality, such as video capturing and analysis at high speeds, light and sound signalization, and speed and contrast measurement.

To assess the AI performance on the edge, and prepare a complete estimation of redesign efforts, our team performed:

-

A purchase of Nvidia development board & environment setup

-

Preliminary firmware source code migration from the initial solution

-

Work Breakdown Structure creation

-

Main components selection

For the client to avoid additional efforts and molding expenses, we selected the optimal ready-made enclosure requiring minimum modifications.

While estimating, PSA foresaw possible bottlenecks and made adjustments regarding:

-

Maintaining image quality without sacrificing speed

-

Optimization of memory usage for the accelerated video recording

-

Device protection against external objects

-

Power consumption, thermal regime, and powering

-

Alarm features, lighting control, and camera placement

-

Licensing issues

-

Additional visual standards support

Thus, the client gained a description of an elegant defect detection solution with server-free AI operation, which significantly unloads industrial networks. Also, the redesigned solution would simplify mounting and allow for avoiding errors during data transfer.

A complete documentation packet includes a project plan and risk plan, a quote with future project estimation, an architecture description, and product cost estimation.

Development Included

- Board procurement

- Architecture design

- Firmware migration

- Components selection

- Documentation creation

Results

-

A complete assessment of product transfer efforts

-

The project on the product transfer is about to start

Technology Breakdown

- 2 SW Engineers

- 4 months