Universal Drive Configuration Tool

Highlights

PSA was engaged by a global manufacturer specializing in application-engineered fractional-horsepower motor and motion products, serving industrial, commercial, and consumer markets. The client was preparing to launch a new product, the Universal Drive, designed to simplify engineering processes across multi-application, flexible manufacturing environments.

Challenge

Customer Challenge

To launch the Universal Drive product while ensuring it offers seamless and user-friendly configuration capabilities for its target users – professional engineers.

Project Objective

Develop a desktop app that enables end-users to configure the Universal Drive across multiple motor types, supporting diverse use cases while remaining simple and efficient.

Solution

To ensure accurate alignment with product goals, PSA’s team visited the client’s facility to gather technical requirements and user expectations for the Universal Drive Configuration Tool.

Working closely with the client, we defined and then implemented key user functionalities, including:

-

Creating and managing drive configuration projects

-

Searching and storing motor and drive parameters in a local database

-

Communicating with attached drives via USB

-

Retrieving real-time operational values from drives

-

Performing firmware checks and updates

-

Supporting multi-language UI selection

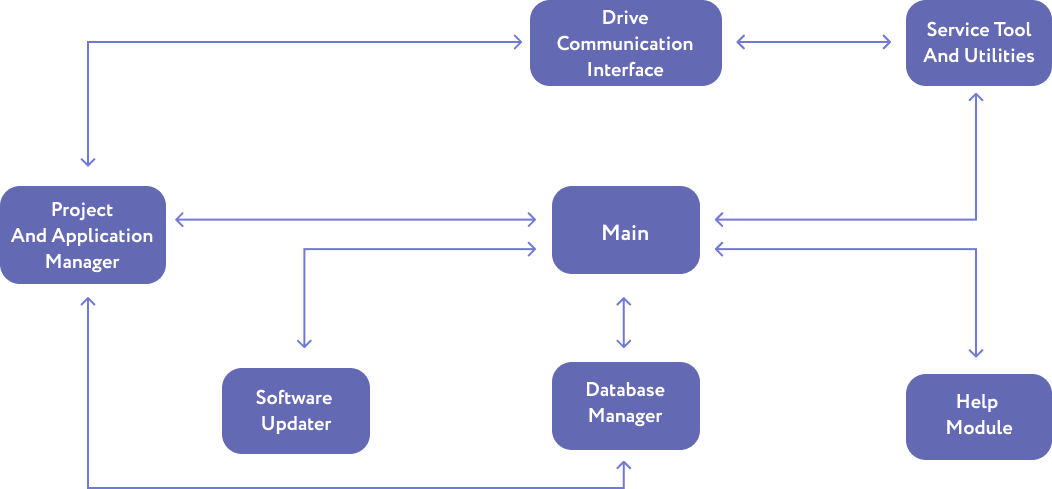

We selected USB as the optimal communication protocol for real-time data exchange and drive configuration. PSA chose the appropriate technology stack, designed the system architecture, and developed the application interface with a focus on user experience (UI/UX). We also implemented an internal API and custom communication library to handle drive interactions within the app.

The PSA team helped the client realize the enhanced product packages – Standard and Factory modes – to enable access to advanced drive parameters and special tools.

At the output, the client got the source code, installation package and user guide. The tool helped the client to successfully launch a new driver type, designed for simple and cost-effective coordination of various motor types.

Development Included

- Requirements clarification

- User stories creation

- Architecture design

- Software design and development

- Firmware development

- Communication library development

- Minimum Viable Product (MVP) development

- GUI development

- Storyboards creation

- Documentation creation

- Functional and performance testing

Result

-

The new product has been launched to market

- Sales increased by 7% following launch

Technology Breakdown

Further cooperation

The customer was satisfied with our working speed, delivery on time and within the budget. They then entrusted us with the support project, which was aimed at adding new features to the delivered tool. Subsequently, we added support for new drive firmware versions, added new functions and types of motors to the database, and improved the interface.