Train Control System Testing for a Mining Railroad

Highlights

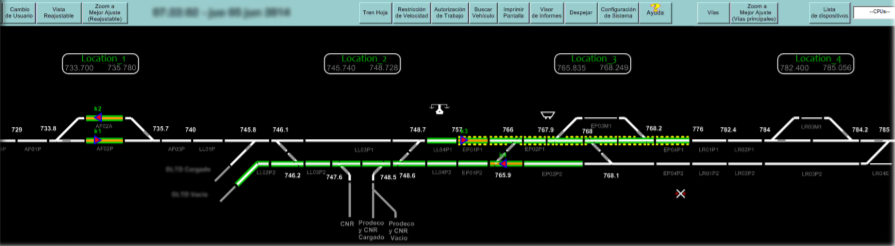

Our customer, a globally recognized multi-industry company, was challenged to optimize rail traffic for 152 miles of a mining railroad that included 15 control points. They intended to implement a SCADA system allowing for train control functions, and contacted PSA for independent Validation & Verification (V&V) activities. The delivered system would provide planning of train movements, track authorities, and asset management capabilities for railroad signaling solutions.

Challenge

Client Challenge

Optimize train movements to provide an efficient mineral transportation process.

Project Objective

Verify and Validate that the integrated SCADA / Train Control system provides safe and efficient rail operation management.

Solution

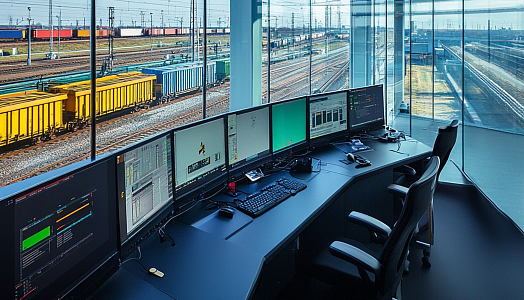

The PSA team needed to validate that the Train Control system provided reliable centers for transport and operation management, as well as communication centers. Thus, we tested the Train Control software functionality within the entire system. This included redundant virtual servers, storage area networks (SANs), Train Controller workstations, Maintenance/Training workstations, and application software.

To ensure complete V&V procedures, our team performed functional and acceptance testing activities both remotely and onsite at the client facilities. The following activities most accurately describe these processes:

-

Reviewing and updating test cases to cover all kinds of rail scenarios

-

Ad hoc testing to get preliminary test results

-

Conducting functional tests for a number of software releases, including verification of all system functions

-

Investigation of any detected system problems

-

Validation of solutions to any found software defects

-

Onsite Factory Acceptance Testing for authorities & restrictions, track line, shift diaries, and train shift capabilities

-

Reporting test results with description of detected failures

To complete the acceptance part, test-case definitions were prepared for FAT procedures, including simulations. Our engineers tested all system capabilities, such as authorities & restrictions, track line, and shift diaries.

During the project, our team was forced to adjust to new requirements that were implemented after the project started, performing re-testing, and conducting more onsite visits.

Ultimately, we completed 501 requirements and provided 98% code coverage for the train control software, thus verifying the system complied with all the specifications and satisfied the request of the mining railroad’s authorities.

Development Included

- Onsite System Training

- Test Procedures Update

- Test Procedures Update

- Requirement Verification Trace

- Factory Acceptance Test Procedures

- Capability Testing

- Factory Acceptance Testing

- Defect Release

- Final Delivery

Results

-

An advanced train control system was successfully implemented for 152 miles of a mining railroad

-

The efficiency of mineral transportation processes increased by 20%