Fuel Dispensing System

Highlights

In 2018, we were contacted by a supplier of wireless fuel management solutions, whose product line opens great opportunities for advanced BI for fuel distributors, commercial fleets, and automotive aftermarket companies. The Fuel Dispensing System is one of the client’s products that allows tracking of fuel consumption by users, which made the system widely used within private fueling stations. Since the solution contained 3rd party hardware, its production, maintenance, and customer support were too costly with the average set of functions. This forced the customer to “redevelop” the existing system to expand its functionality and reduce the cost of its components.

Challenge

Client Challenge

Reduce the cost of production of the fuel dispensing system hardware, while expanding the range of its use cases.

Project Objective

Develop an alternative fuel dispensing solution with extended functionality and more affordable hardware components.

Solution

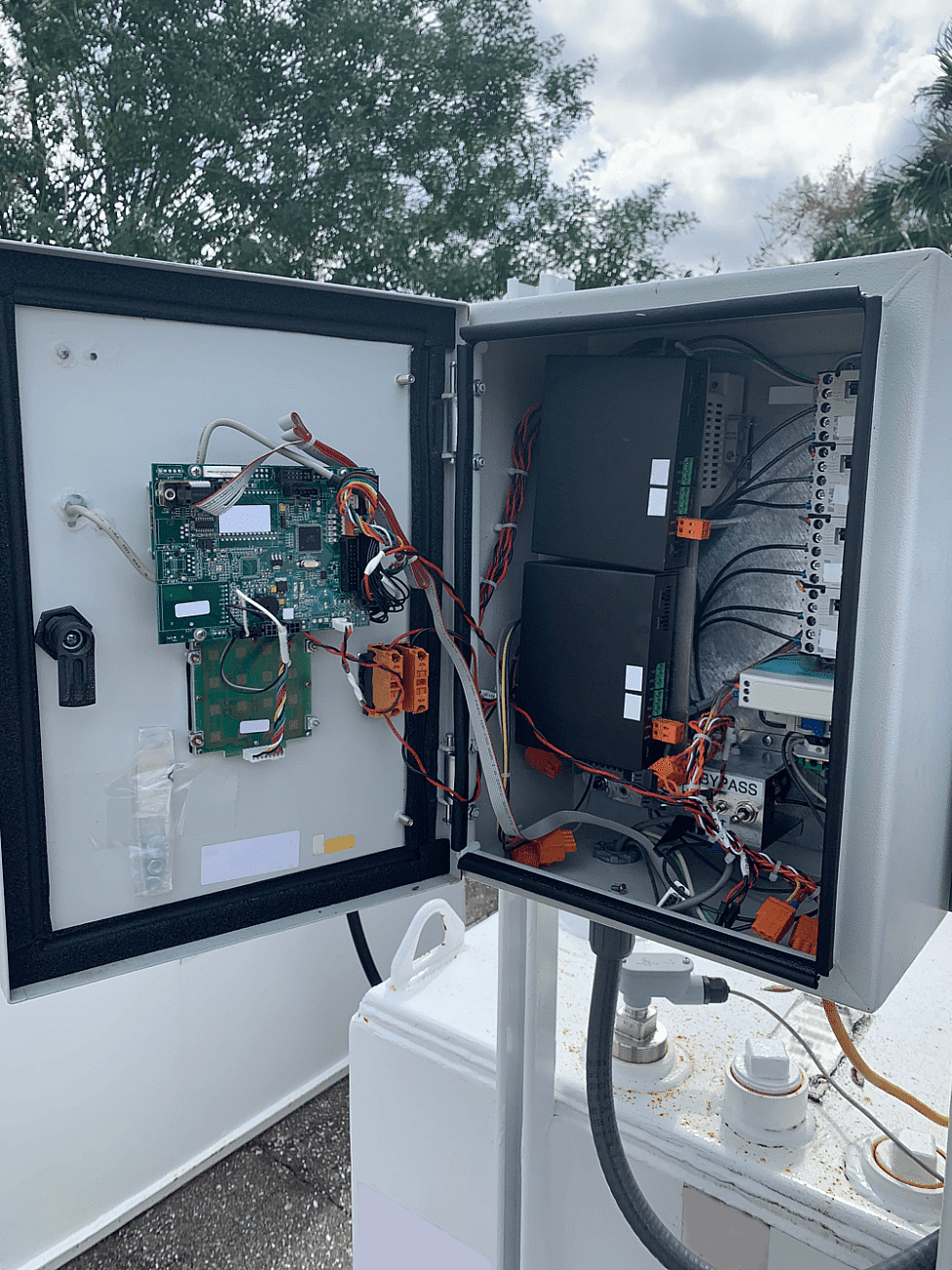

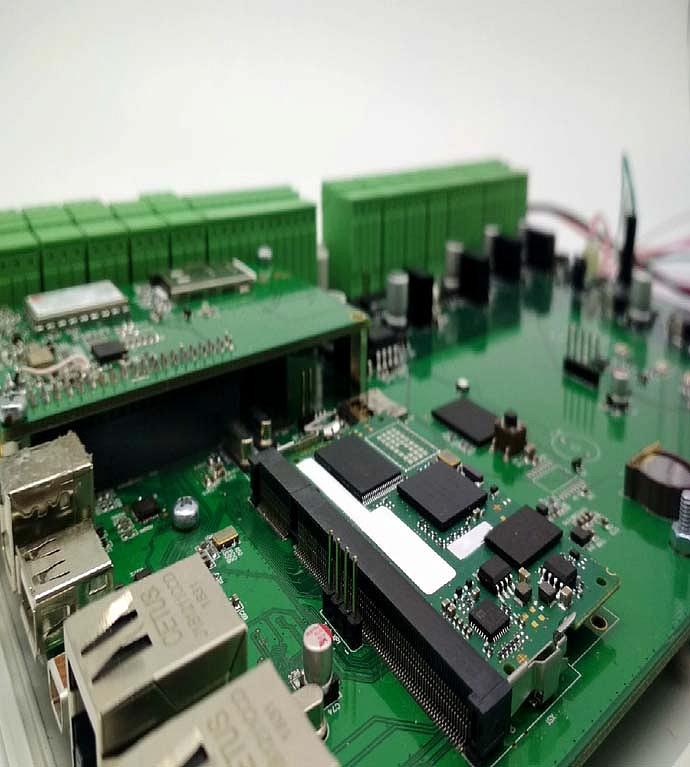

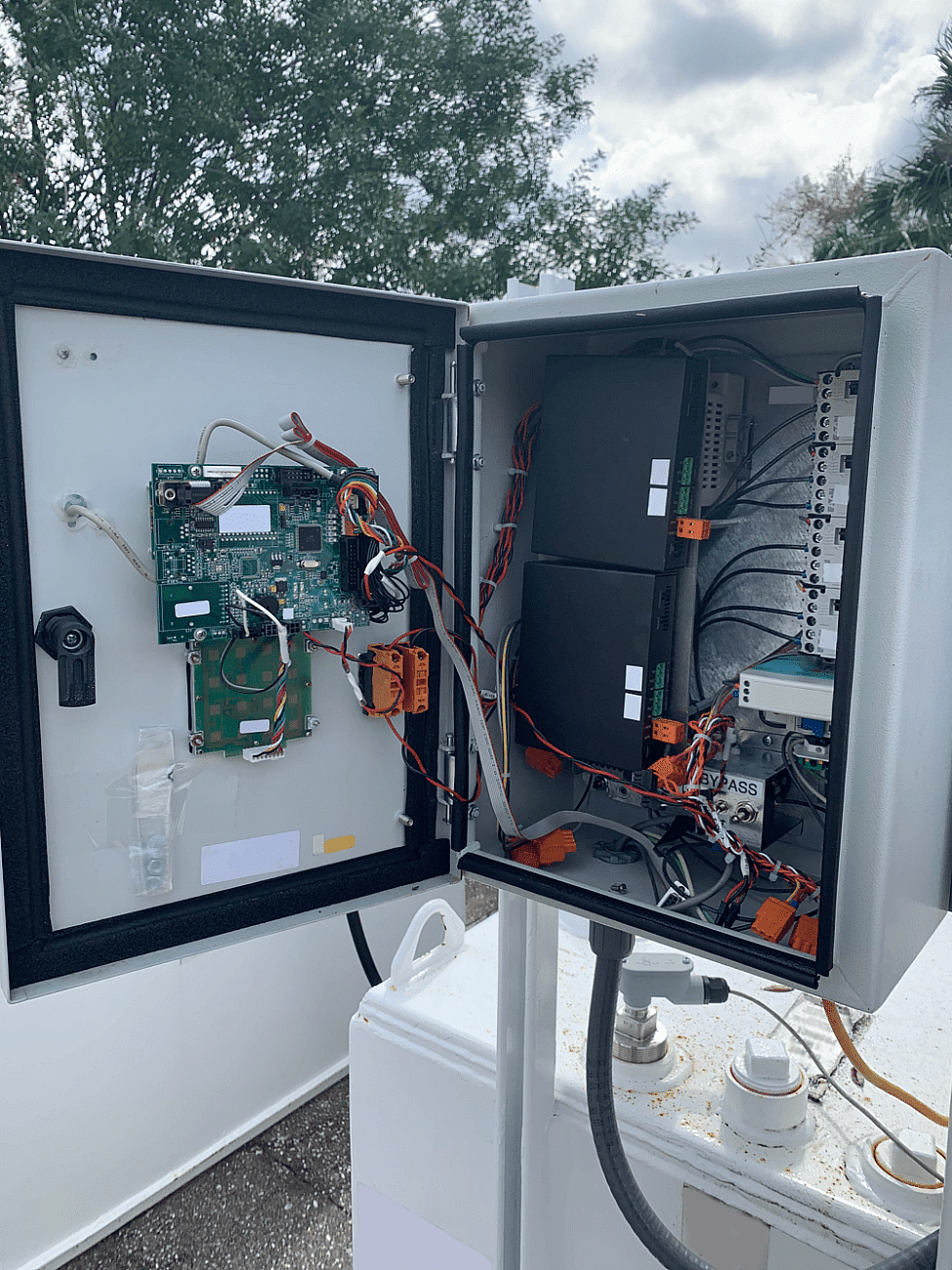

The PSA team developed the Fuel Dispensing System with access control and fuel level tracking which enables sharing of fuel tanks. To lower the cost of the components we designed and developed the customized hardware for the system which consisted of the following:

-

A fuel pump controller that is integrated with a pump, collects and processes the data from sensors, and sends it to the server

-

Control pad that allows for management of the system and provides visual and audio signals

Guided by the DFM approach, we optimized the cost of HW production by selecting reliable and efficient components and modules provided by our partner Toradex at affordable prices. Since the customer hadn't provided us with the components and suppliers they preferred, we utilized our own expertise and conducted detailed market research, defined functional requirements, and chose cost-effective and weather-resistant components that fully satisfied the functional requests.

We provided the Fuel Dispensing System with the following features:

-

Wireless (Bluetooth, WiFi) and cellular (4G) communication networks

-

GPS navigation

-

Support of large screen color displays

-

Advanced technology in data management

-

Backward compatibility with existing hardware and software

To ensure this, we performed schematics, PCB-layout, and mechanical design for both the Fuel Pump Controller and the Control Pad, then developed firmware for them. After developing and flashing the system, the Control Pad freely communicates with the Fuel Pump Controller that communicates with the web server.

The Control Pad that we developed supports the LCD display, keypad, keyboard, and LEDs matrix. Access is controlled via iButton, Magnetic card, and RF Tags. We ensured its protection from intruders and operation in harsh conditions through tamper-proof housing.

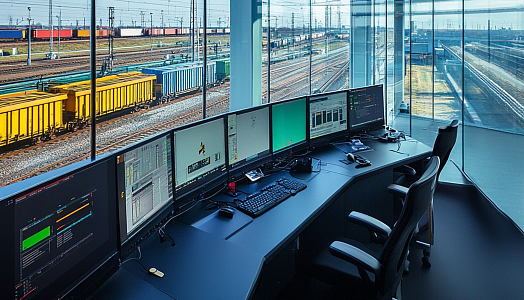

To manage the Fuel Dispensing System and monitor fuel consumption, we developed a web configuration console that allows display of:

-

Online status of the Fuel Dispensing System

-

Internet connection

-

Fuel Pump Controller and the Control Pad status

-

Fuel level, overfill, and interstitial sensors status

-

White list of the users/vehicles

-

Pump motor status

-

Current and last counters

We ensured full control of the whole Fuel Dispensing System status and provided the users with data about the processor, allocated and free memory, OS and firmware versions, LEDs, system uptime, and app’s start count.

At the output, the client got 5 tested PoC hardware units for the Fuel Pump Controller and the Control Pad which can be controlled and updated remotely. The system was accompanied by documentation that allows for launch to mass production.

Development Included

- Requirements definition

- Hardware components selection

- Schematics design

- PCB development

- Enclosure design

- Firmware development and implementation

- UI development

- Bring-up and testing of prototypes

- Product documentation

- Continuous support

Results

-

Production cost reduced by 30%

-

The smaller system’s size facilitates its delivery and installation

-

Wi-Fi, 4G, Bluetooth, GPS, and LSD display added

-

Ready to be launched in mass production