Dosimeter Calibration Management Tool

Highlights

Our client – a globally represented supplier of scientific instrumentation – involved PSA in their efforts to optimize the dosimeter calibration process that is executed using a range of radiation sources. Intending to launch a new generation of personal handheld dosimeters, they augmented the calibration equipment with a new device compatible with both existing and upcoming models of dosimeters. The crucial step of this optimization was to provide an opportunity for real-time remote monitoring and control of the whole calibration process for all types of dosimeters, including configuration, opening of the radiation source, and the transportation of dosimeters between irradiation stations.

Challenge

Client Challenge

Reduce the costs for calibration of personal handheld dosimeters considering the launch of the new model.

Project Objective

Ensure precise and convenient calibration for multiple types of dosimeters while also increasing process performance.

Solution

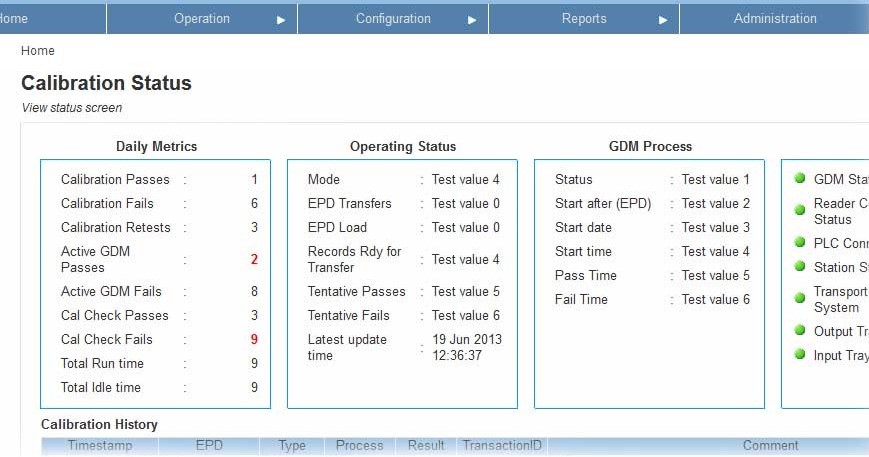

To provide comprehensive management of the dosimeter calibration processes, the PSA team developed desktop and web tools that allow for control of the augmented calibrating machine. In real-time, the application collects and sends data to dosimeters under calibration, the transportation system of the calibrating machine, and the irradiation source module, which contributes to the following functionality:

-

Radiation dose management for the particular types of dosimeter; open/close status for exposure source

-

Establishment of position for dosimeters, and their moving between irradiation stations at the required direction

-

Adjustment of dosimeters’ settings in accordance with their response to exposure

-

Delivery of calibration reports and provision of secure automatic data export to the centralized production management system

-

Studying the history of dosimeters calibration configuration, process, and results

The PSA team designed the application from scratch starting with the complex architecture design, followed by implementing algorithms for dosimeters calibration, developing UI, and conducting onsite testing. During the project, we utilized real client dosimeters and IR readers, simulating doses and detector counts, and the imitation of the robotic system that transports the dosimeters between irradiation stations.

To ensure performance is maintained in terms of data size increases, we connected the app to an SQL server. Also, our team implemented multi-tasking for the updated calibrating machine, which allows for simultaneous irradiation of several dosimeters. These features together with a responsive UI contributed to the ultimate performance and throughput of the system.

As a result, the threshold and sensitivity of the various types of client-produced dosimeters are set in adherence with the instructions of the PSA-delivered app. The client receives calibration verification, analysis, and reporting for every produced dosimeter, which helps verify the devices beforesale. The high accuracy of calibration allows for the usage of personal handheld dosimeters for scientific, industrial, medical, and other purposes.

Development Included

- Requirements definition

- Architecture design

- Software development

- Algorithms implementation

- GUI development

- Functional testing

- Integration & site acceptance testing

- User and maintenance guide creation

Results

-

Productivity has doubled

-

Calibration costs have been reduced

-

Extendable to include future models